PLD: Two major advances for more efficient depositions

In 2024, the Pulsed Laser Deposition (PLD) platform at IPCMS in Strasbourg benefited from two major instrumental advancements: the integration of a sputtering system and the addition of a laser heating system for samples. This funding was provided as part of the SPINMAT Targeted Project under the SPIN Research Program.

Now directly connected to one of the PLD chambers, the sputtering chamber enables sequential depositions without interruption or exposure to air, thereby optimizing the quality of thin films. Custom-assembled by the platform team, this setup includes a 2-inch DC magnetron, specifically designed for depositing metallic materials such as platinum or copper. Combined with the functional oxides developed by the “Thin-Film Oxides” team, this innovation opens new perspectives in spintronics.

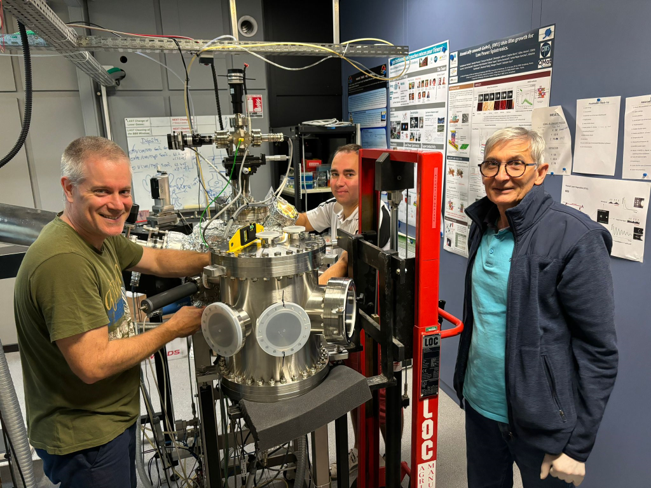

People who installed these new features

From left to right : François ROULLAND (MCF), Laurent SCHLUR (IE), Gilles VERSINI (IE)

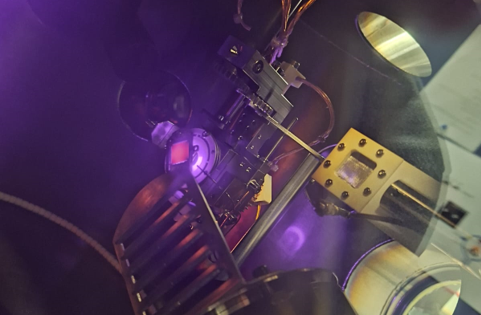

Laser heating : now able to heat the samples up to 1100°C at 50°C per minute